Exploring the Vital Applications and Utilizes of Light Weight Aluminum Foundry in Modern Production

Light weight aluminum shops play a crucial role in contemporary production, offering varied markets with their distinct buildings. From auto components that boost gas performance to aerospace frameworks that prioritize weight, light weight aluminum's versatility appears. Its applications reach building and construction and consumer electronic devices, highlighting its resilience and power performance. Nonetheless, the innovations in aluminum casting techniques and future fads warrant a closer exam, as they might redefine its influence on production.

The Role of Aluminum Foundries in Automotive Manufacturing

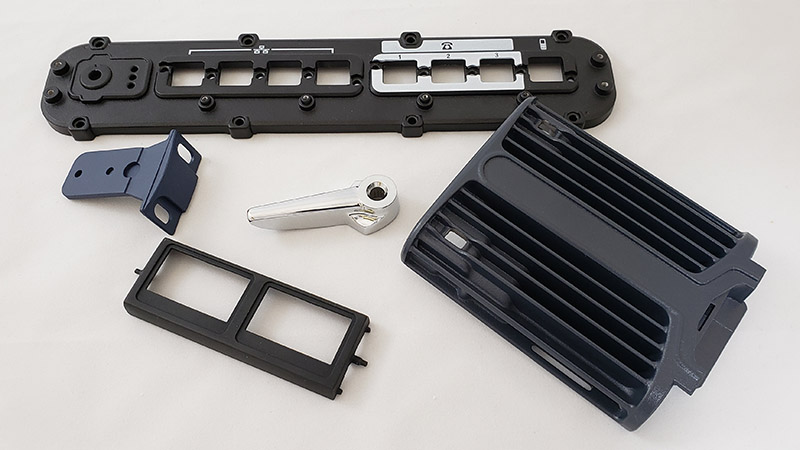

As the automobile sector progressively focuses on lightweight products to enhance gas effectiveness and efficiency, light weight aluminum factories have actually become vital contributors to manufacturing procedures. These factories specialize in producing components that fulfill the rigorous needs of contemporary cars, such as engine blocks, transmission real estates, and structural aspects. Light weight aluminum's beneficial residential or commercial properties-- such as high strength-to-weight proportion, corrosion resistance, and superb thermal conductivity-- make it a perfect choice for automotive applications.

Light weight aluminum shops use sophisticated spreading methods, including die spreading and sand spreading, to develop durable and complex components. This ability enables producers to optimize designs for performance while lessening weight. Making use of light weight aluminum additionally supports sustainability goals, as it is highly recyclable and lowers energy usage in lorries. By assisting in the integration of aluminum into vehicle design, factories play an essential function fit the future of the automotive sector, promoting performance and innovation across the board.

Aerospace Applications: Lightweight Solutions for Trip

Aluminum factories play a significant duty in the aerospace industry, where the need for light-weight products is vital for enhancing gas effectiveness and performance in airplane. The one-of-a-kind residential properties of light weight aluminum, including its high strength-to-weight proportion and rust resistance, make it an excellent option for different aerospace parts. These parts include architectural parts, engine cases, and landing equipment, which add to overall airplane efficiency.

Making use of light weight aluminum alloys, specifically those developed via innovative casting techniques, permits the production of detailed designs and complex shapes while minimizing weight. In addition, aluminum's recyclability lines up with the aerospace sector's sustainability goals, lowering environmental influence. With constant advancements in light weight aluminum foundry innovations, manufacturers can enhance production procedures, bring about raised performance and decreased expenses. As the aerospace industry significantly prioritizes technologies that boost performance, light weight aluminum shops will certainly remain integral to creating lightweight services for modern trip.

Structure and Building: Enhancing Architectural Honesty

In the structure and construction market, a significant focus is put on boosting structural integrity through making use of light weight aluminum. Recognized for its high strength-to-weight proportion, light weight aluminum provides resilience without compromising on weight, which is important in modern-day architectural designs. Its resistance to rust further guarantees long life, making it an excellent material for different architectural elements, including beam of lights, structures, and cladding.

Light weight aluminum also assists in innovative style opportunities, enabling engineers and designers to produce visually pleasing frameworks while keeping safety and security standards. The material's flexibility enables its application in both commercial and residential tasks, from high-rise buildings to bridges. In addition, developments in aluminum factory strategies have actually boosted the accuracy of light weight aluminum components, guaranteeing they fulfill strict building ordinance. Generally, the assimilation of aluminum in building and construction not just boosts structural stability however additionally adds to lasting building methods, offered its recyclability and energy-efficient manufacturing techniques.

Consumer Electronics: The Rise of Aluminum in Modern technology

In the domain name of customer electronic devices, aluminum has obtained importance due to its lightweight style advantages and superior thermal conductivity. This shift not just boosts product transportability but likewise enhances device performance by properly dissipating warmth. As innovation remains to evolve, the duty of light weight aluminum in developing sleek and reliable gadgets is significantly significant.

Light-weight Design Advantages

As customer electronics progress, the demand for lightweight yet long lasting products has actually surged, making light weight aluminum a significantly prominent selection among suppliers. Its reduced thickness permits the creation of smooth devices that are simple to utilize and carry, considerably enhancing transportability. The strength-to-weight ratio of aluminum warranties that items can endure everyday wear and tear without jeopardizing performance. Additionally, the pliability of light weight aluminum enables makers to develop detailed forms and forms, even more adding to innovative aesthetics and performance. This light-weight quality likewise plays an important function in power performance, as lighter gadgets require much less power to run. Because of this, light weight aluminum not just meets the evolving visual demands but additionally straightens with the contemporary emphasis on sustainability in customer electronic devices.

Thermal Conductivity Perks

Thermal conductivity is an essential variable in the performance of customer electronic devices, and aluminum excels in this domain. Its high thermal conductivity permits effective warm dissipation, which is necessary for keeping ideal operating temperature levels in devices such as smartphones, laptop computers, and gaming consoles. By facilitating quick warm transfer far from sensitive parts, aluminum assists avoid overheating, thus boosting performance and extending gadget longevity. The light-weight nature of aluminum enhances its thermal buildings, making it a perfect option for portable innovation. As producers significantly prioritize performance and energy efficiency, aluminum's function in thermal monitoring becomes even extra significant, bring about its expanding fostering in modern electronic designs. This fad find this highlights light weight aluminum's significance in customer electronics development.

Marine Sector: Rust Resistance in Harsh Settings

Deterioration resistance is a vital aspect in the aquatic sector, where devices and frameworks are regularly exposed to extreme saltwater settings. Aluminum, specifically in its alloy kinds, provides significant advantages in this respect. Its all-natural oxide layer provides a protective barrier that prevents corrosion, making it excellent for vessels, docks, and various other marine applications.

Marine-grade light weight aluminum alloys, such as 5083 and 6061, are particularly created to withstand the corrosive results of deep sea and weather. These alloys not only withstand deterioration however likewise maintain structural integrity and toughness gradually. Applications vary from hulls and superstructures of ships to elements in overseas platforms.

The lightweight nature of aluminum further enhances its viability, making it possible for enhanced fuel performance and convenience of handling - aluminum casting company. As the marine industry remains to concentrate on resilience and performance, light weight aluminum remains an essential material option for resisting corrosion sought after marine settings

Advancements in Light Weight Aluminum Spreading Techniques

While typical aluminum spreading techniques have served the market well, recent technologies are transforming the landscape of light weight aluminum production. Techniques such as 3D printing of molds and cores are obtaining grip, permitting rapid prototyping and reduced lead times. This advancement makes it possible for makers to create intricate geometries that were formerly tough to accomplish with traditional spreading methods. Furthermore, developments in die-casting modern technology, including making use of high-pressure die-casting (HPDC), have boosted the precision and surface area finish of cast aluminum parts, leading to enhanced efficiency in numerous applications.

The adoption of investment spreading has enabled for better design flexibility and decreased material waste. Innovations in alloy compositions are also substantial, as they boost mechanical residential or commercial properties and corrosion resistance. In general, these advancements not only simplify production processes but also contribute to more lasting practices within the light weight aluminum foundry sector, making it versatile to the evolving demands of modern manufacturing

Future Trends in Light Weight Aluminum Foundry Manufacturing

The future of light weight aluminum factory production is positioned for substantial improvement through automation, enhancing efficiency and precision in manufacturing procedures. Lasting practices are progressively becoming a top priority, as shops seek to minimize their environmental influence while fulfilling expanding governing demands. In addition, advancements in alloy growth will allow the development of more powerful, lighter materials tailored for varied applications, driving innovation in the market.

Automation in Factory Processes

Lasting Production Practices

An expanding emphasis on sustainable production methods is improving the future of light weight aluminum factory manufacturing. Industry leaders are increasingly taking on energy-efficient technologies and reusing initiatives to lessen waste and minimize carbon footprints. Using recycled aluminum substantially reduces energy consumption contrasted to main light weight aluminum manufacturing, making it a favored selection for eco aware makers. Additionally, cutting-edge spreading strategies are being developed to enhance material performance and reduce emissions. Companies are also buying eco-friendly energy resources, such as solar and wind, to power their operations sustainably. aluminum casting company. By integrating these practices, the light weight aluminum shop market not just fulfills regulatory requirements but also reacts to consumer demand for greener products, inevitably leading the way for a more sustainable production landscape

Advanced Alloy Advancement

Advancements in aluminum alloy growth are readied to More about the author play a substantial role in the future of shop manufacturing, especially as sustainability and efficiency demands intensify. The industry is increasingly focusing on developing high-strength, light-weight alloys that can endure severe conditions while minimizing environmental impact. Scientists are exploring ingenious structures, such as aluminum-lithium and aluminum-scandium alloys, which assure improved mechanical buildings and decreased weight. In addition, the assimilation of sophisticated manufacturing strategies, consisting of additive production and precision spreading, enables even more complicated geometries and lowered material waste. As governing stress and consumer choices shift towards greener options, the growth of energy-efficient and recyclable alloys will be essential. The future landscape of light weight aluminum foundry production pivots on these improvements in alloy technology.

Frequently Asked Questions

What Are the Environmental Influences of Aluminum Shop Operations?

Light weight aluminum foundry procedures can lead to considerable ecological effects, including greenhouse gas emissions, power consumption, and waste this generation. In addition, incorrect monitoring of contaminants may bring about soil and water contamination, affecting local ecological communities and neighborhoods.

Just How Does Light Weight Aluminum Recycling Affect Foundry Processes?

Aluminum reusing improves factory procedures by providing a cost-efficient raw material, lowering power usage and exhausts. This sustainable practice raises effectiveness, minimizes waste, and sustains the round economic situation, profiting both makers and the environment.

What Precaution Are Applied in Light Weight Aluminum Foundries?

Light weight aluminum foundries execute different security measures, consisting of personal protective devices, correct air flow systems, normal security training, fire avoidance procedures, and equipment maintenance procedures to lessen threats and guarantee a risk-free working environment for all workers.

Exactly How Do Foundries Guarantee Top Quality Control in Light Weight Aluminum Casting?

Foundries ensure high quality control in light weight aluminum spreading through strenuous material evaluations, specific temperature level surveillance, standardized procedures, and regular testing of cast items. These measures aid maintain consistency, reduce defects, and meet market requirements properly.

What Are the Expense Consider Light Weight Aluminum Shop Production?

Price consider aluminum shop production include resources prices, power intake, labor prices, tools maintenance, and overhead costs. Additionally, manufacturing quantity and complexity of designs considerably influence overall production costs and earnings.

As the auto industry increasingly prioritizes light-weight materials to boost fuel efficiency and efficiency, aluminum factories have actually ended up being vital contributors to making processes. Light weight aluminum shops play a substantial role in the aerospace market, where the demand for light-weight products is paramount for boosting fuel performance and performance in aircraft. Furthermore, advancements in light weight aluminum foundry methods have enhanced the precision of light weight aluminum elements, guaranteeing they satisfy rigid structure codes. While traditional light weight aluminum casting methods have actually served the industry well, recent developments are transforming the landscape of light weight aluminum production. The use of recycled aluminum considerably reduces power intake contrasted to main aluminum production, making it a recommended selection for ecologically aware suppliers.